| |

|

|

|

|

| |

|

|

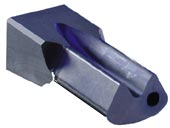

The tool and die roots of Ultra Precision centered around traditional

grinding capabilities. The employees back in the early years of the

company could only have dreamed about the type of work being performed

in Ultra Precision's EDM department. What was fantasized about many

years ago is not only a reality today, but a reality that is still

growing and expanding.

|  |

|  |

The advent of more intricate die designs brought on by today's

wave of technological advances, has given birth to an exceptional

area of expertise in Ultra's already far reaching team of toolmakers.

The EDM department consists of two parts, standard EDM and wire EDM.

While both can stand alone, teamed together they make almost any tooling

request plausible for fabrication. Both departments are equipped with

state of the art machines. However, as with any machine, the person

behind the controls is what makes the operation run.

|

|

This is where

Ultra can separate itself from the competition. None of the

individuals in this department are strictly "button-pushers".

Each person is trained to program and debug the machine.

By becoming intimately aware of the machines' capabilities and

operating procedures, these employees can handle the most arduous

dimensional requirements and tolerances.

|

|

|  |

These superior machines

and workers also spell the end to the crusty finishes later day EDM

machines used to produce. In fact, with a polishing facility

contained within the department, any micro finish request is feasible.

To make this department even more customer-friendly, bear in mind that it

is in operation around the clock. Utilize this department and your lead

time headaches are alleviated and your dies run trouble-free. |

|

|

|

|

|

|

|

|